Whether reflow, wave or hand soldering, surface tension is a detriment to forming a good solder joint. However, surface tension can be used in SMT patch processing and reflow soldering. When the solder paste reaches the melting temperature, the balanced surface...

1. Measures to change surface tension and viscosity

Viscosity and surface tension are important properties of solder. A good solder should have low viscosity and low surface tension when molten. Surface tension is the nature of matter, it cannot be eliminated, but it can be changed.

The main measures to reduce surface tension and viscosity in PCBA welding are as follows:

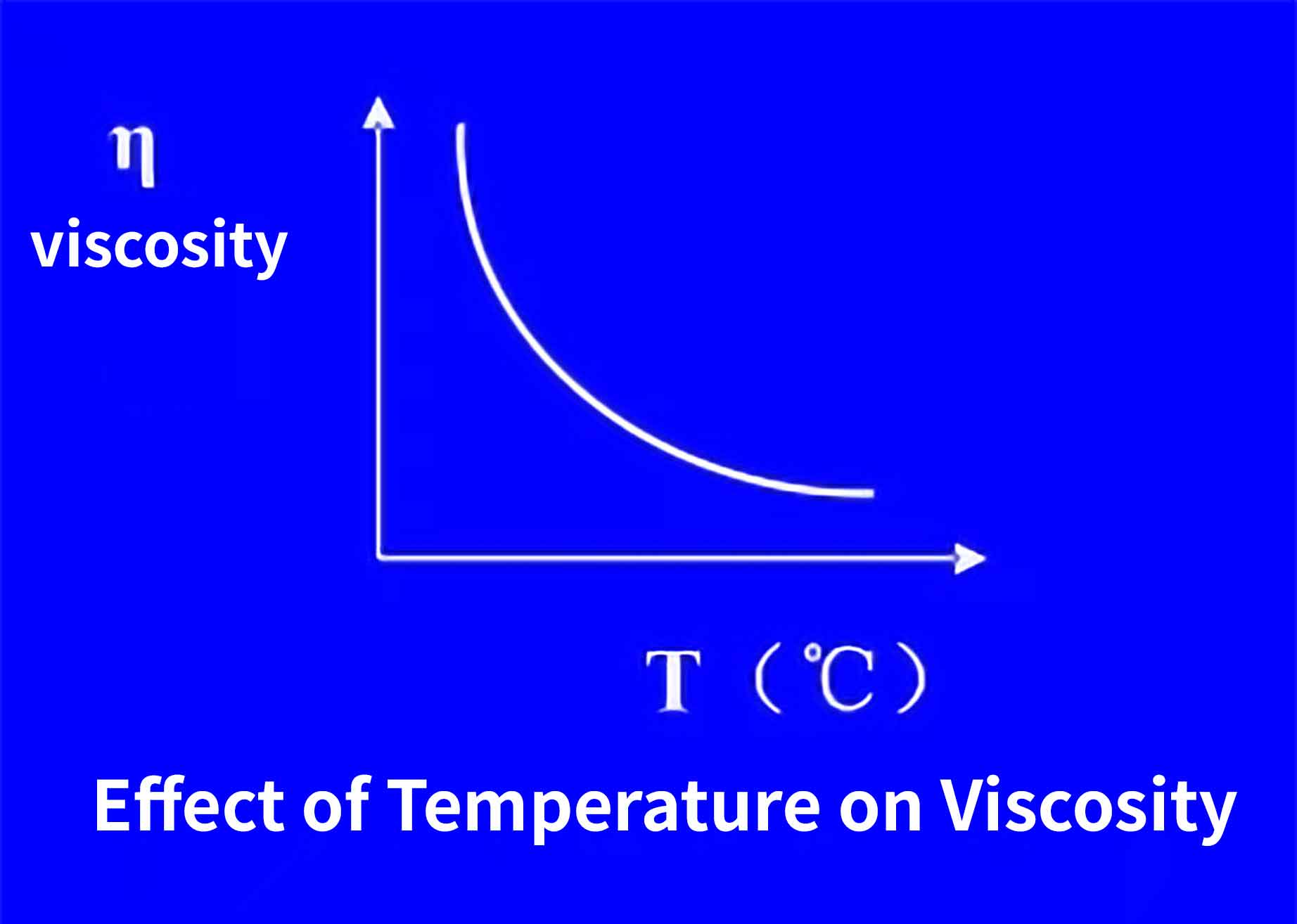

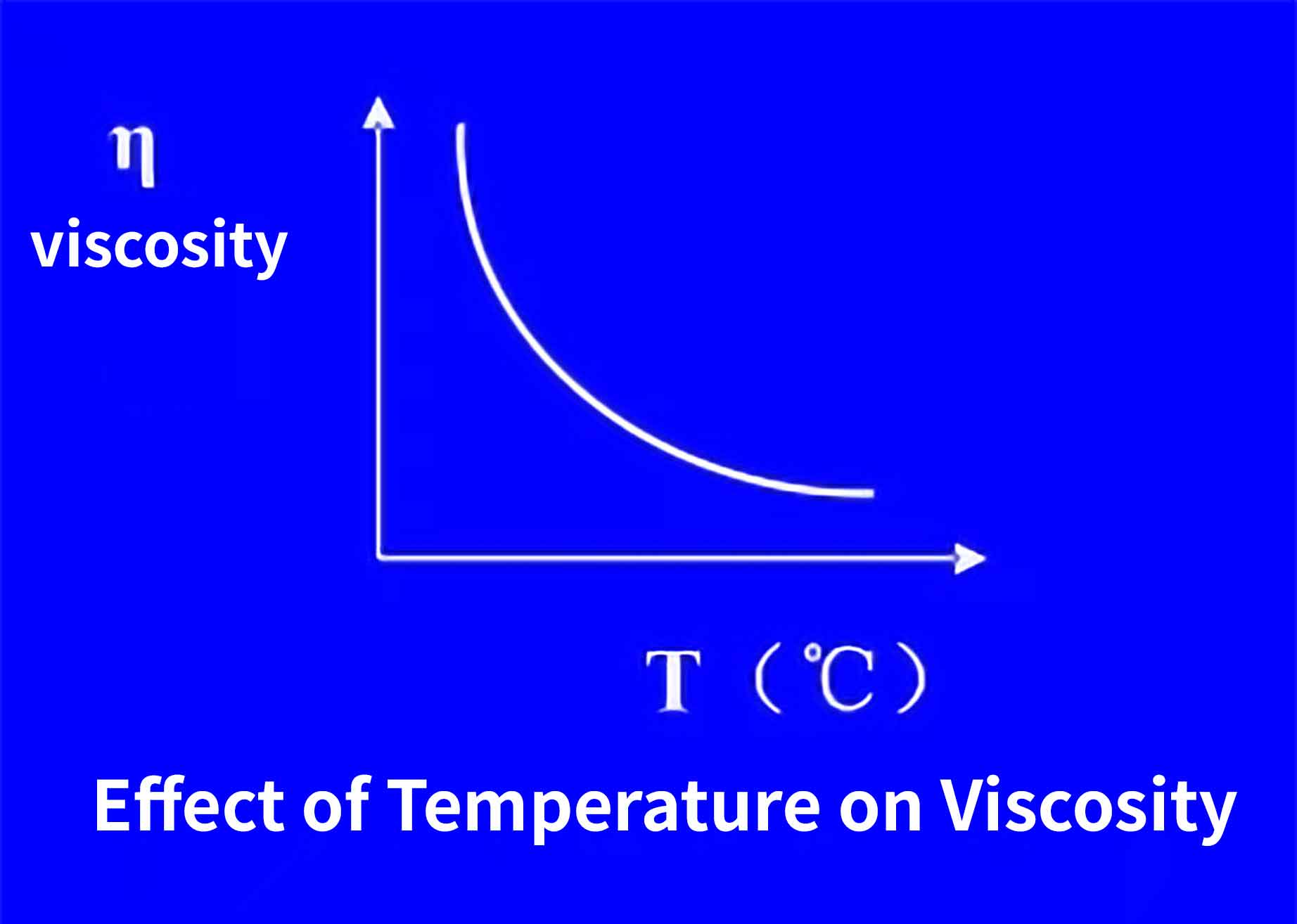

Increase temperature. Elevating the temperature can increase the molecular distance in the molten solder and reduce the attractive force of the molecules in the liquid solder to the surface molecules. Therefore, increasing the temperature can reduce the viscosity and surface tension.

Adjust the metal alloy ratio. The surface tension of Sn is very high, increasing Pb can reduce the surface tension. It can be seen from the figure that when the content of lead increases in Sn-Pb solder, when the content of Pb reaches 37%, the surface tension decreases obviously.

Increase the active agent. This action can effectively reduce the surface tension of the solder, and can also remove the surface oxide layer of the solder.

Improve the welding environment. The use of nitrogen protection pcba welding or vacuum welding can reduce high temperature oxidation and improve wettability.

2. The role of surface tension in welding

Surface tension is in the opposite direction to the wetting force, so surface tension is one of the factors that are not conducive to wetting.

Whether reflow, wave or hand soldering, surface tension is a detriment to forming a good solder joint. However, surface tension can be used again in SMT chip processing and reflow soldering.

When the solder paste reaches the melting temperature, under the action of balanced surface tension, there will be a self-alignment effect (Self Alignment), that is, when the component placement position deviates a little, under the action of surface tension, the component can automatically is pulled back to the approximate target position.

Therefore, the surface tension makes the reflow process more relaxed in terms of placement accuracy, and it is easier to achieve a high degree of automation and high speed.

At the same time, because of the characteristics of "reflow" and "self-positioning effect", the SMT reflow soldering process has stricter requirements on pad design and component standardization.

If the surface tension is unbalanced, even if the mounting position is very accurate, there will be welding defects such as component position offset, tombstoning, and bridging after soldering.

During wave soldering, due to the size and height of the SMC/SMD component body itself, or because the high component blocks the short component and blocks the oncoming tin wave flow, and is affected by the surface tension of the tin wave flow, the shadow effect is caused on the component body. The back side forms a flow blocking area that cannot be wetted by liquid solder, resulting in solder leakage.