Ability Injection molding, insert molding, secondary molding |

Lead time more than 10 working days |

Tooling Rapid Tooling: Recommended for 100–10,000 parts / Production Tooling: Recommended for 10,000+ parts |

Material Plastics and Resins |

Available machines Single cavity molds, multi-cavity molds, multiple casting molds in one mold; 50 to 1,100+ punch tonnage; side operation includes manual core loading |

Cavity Tolerance ± 0.1 mm for tooling, plus ± 0.05 mm for shrinkage |

Part repeatability ±0.1 mm or less |

Critical Feature Tolerance Tighter tolerances can be achieved upon customer request, but may increase tooling costs due to more spot checks and trimming. In terms of key features, Wellink will mill to conditions that are safe for steel. |

Available mold types Steel (tool steel, carbon steel) and aluminum; production grades range from Type 105 (prototype tooling) to Type 101 (very high production volume tooling). |

|

Fast delivery Our molds have a short delivery time: 10 working days for express tooling and up to 20 days for production tooling. |

|

Continuous production Ideal for production of more than 100 parts. |

|

Accurate Wellink offers tight tolerance options in accordance with ISO 16742, up to ±0,07 mm, depending on the precision of the tool and the dimensions of the part. |

|

Tooling Single-cavity mold, multi-cavity mold, one-mold multi-cast mold options. |

|

Material selection A wide selection of materials allows you to achieve the strength and surface quality you need. |

|

Quality Control Our Quality Assurance department implements a strict quality assurance process. |

| Mold classification | Cycle | Production | Formwork | (BHN)Minimum hardness(BHN) | Description |

| 101 | >1 Million | High | Heat Treated Stainless Steel | 280 | Supports fast cycles for fast production |

| 101 | <1 Million | Mid-high | Heat Treated Tool Steel | 280 | Suitable for parts with abrasives and tight tolerances |

| 103 | <50,000 | Middle | P20 steel | 165 | Widely used for low to medium production volume components |

| 104 | <10,000 | Low | mild steel, aluminium or alloy | <165 | Ideal for parts with limited production volumes, especially those using non-abrasive materials |

| 105 | <500 | Very low | Soft aluminum, epoxy resin, casting material | <165 | Typically used for prototyping |

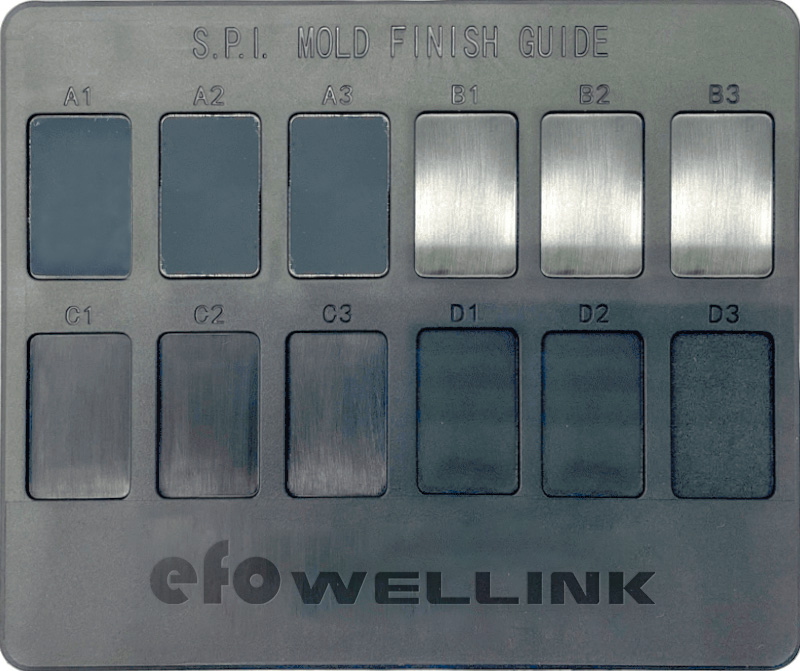

| A1: Diamond - Polish Level 3 (Highly Polished) | B1: Sandpaper 600 (moderate polish) |

| A2: Diamond - Polish Level 6 (Highly Polished) | B2: Sandpaper 400 (moderate polish) |

| A3: Diamond - Polish Grade 15 (Highly Polished) | B3: Sandpaper 320 (medium to low polish) |

| C1: Stone 600 (light polished) | D1: Dry Sandblasted Glass Beads |

| C2: Stone 400 (lightly polished) | D2: Dry Blast 240 Oxide |

| C3: Stone 320 (lightly polished) | D3: Dry blasting 24 oxide |

B-3F, No.19 He Xing Rd, Shatou Chang'an, Dongguan 523866, China.

T: (86) 755-8657 2900

F: (86) 769-8225 4557

E: sales@efocn.com

Copyright© Wellink Industrial Tech (Shenzhen) Co., Ltd.