Before introducing how to execute the function test after pcba processing, it is better to understand how it was executed in the past. The best way to know about the actual test is to visit the PCBA manufacturing plant that produces products similar to your products, and check the entire

production line, from the circuit board into the workshop to the product packaging and shipping. The secret of this is that we can actually experience various processes in the production process, which is very helpful for us to understand how circuit boards are generated. So today we will focus on analyzing the related problems of functional testing:

1、 Functional test plan

Before smt processing of a circuit board, DFM instructions are usually available in the design process. This will keep you in the "design for testability" time plan throughout the design process. It will clearly indicate which test aspects are included in the schematic diagram, PCB layout and even microcontroller code.

For example, what do you expect when a user touches capacitive touch? Maybe it wakes up the screen or turns on the LED and tells the microcontroller to perform the operation. This operation requires that all your components have the correct voltage, that capacitive touch sensors and LEDs are correctly installed, and that the microcontroller is programmed and running as expected. This kind of functional test plan will guide the quality of the whole PCBA circuit board processing.

2、 Test point

The test point is just a PCB pad on the board, which is specially used for easy detection. For various reasons, you do not want to rely on the pins or pads of the probe assembly. The dimensions of these pads are not specified, but they should be large enough to easily contact the test probe.

3、 Programming in the system

If you look at the internal structure of any sufficiently complex product, you may find a space on the programming connector or PCB where the programming connector may be placed. This connector is usually used to program microcontrollers installed on PCB, so it is called "in system". In the mass production scenario, it is meaningless to install this header. It is used by designers for debugging purposes and is not installed during production to eliminate costs.

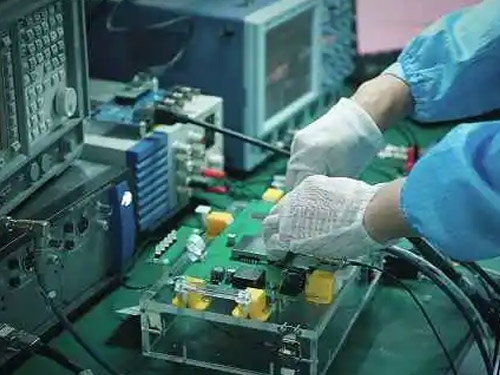

4、 Test fixture

For early prototypes or a small number of designs, you can manually test each board yourself. You will thank your future self for completing this exercise, because it allows you to appreciate and understand what is required to confirm the normal operation of your product. Humans are usually not good at repeatability, so developing a test plan, even with checkboxes, can help you avoid skipping any step.