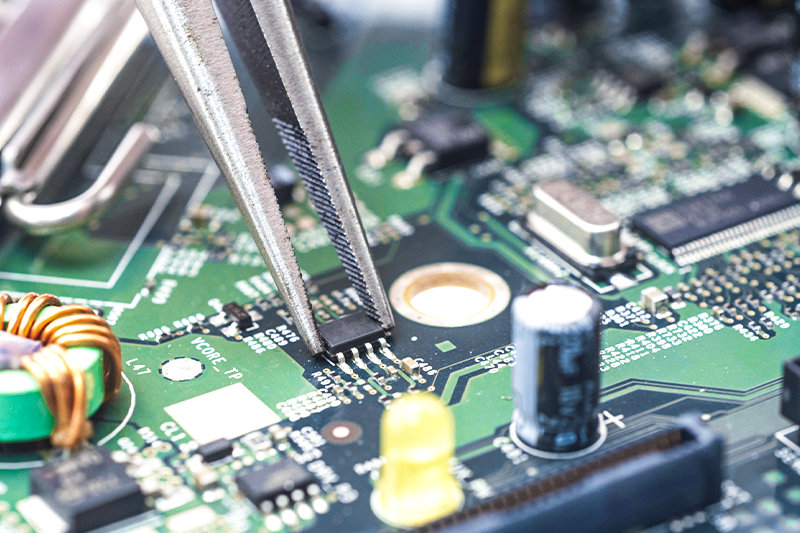

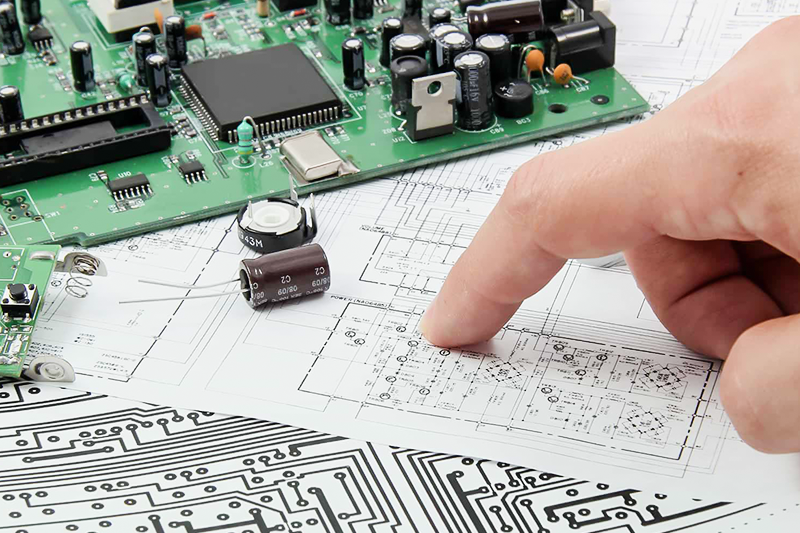

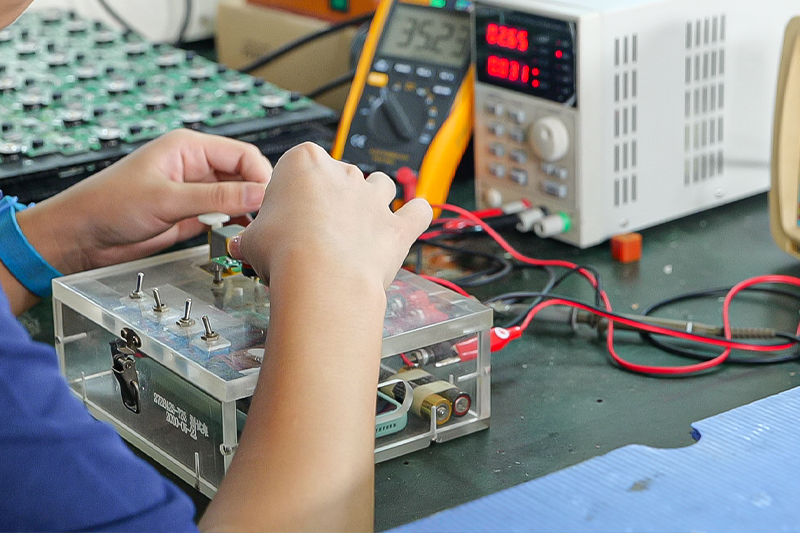

PCB assembly

We are proficient with PCB substrates including rigid board, flex circuit, and rigidflex hybrid circuits. Flexible component placement solutions include surface mount technology (SMT), plated thru-hole technology (PTH, THT) and mixed technology assemblies.